Overview

Operating in the rough and tumble environment of 1/5 scale, a servo’s performance is pushed to the maximum. The S9110BL and S9120BL servos have been designed to give 1/5 enthusiasts huge torque and brushless motor precision, taking their driving experiences to a new level.

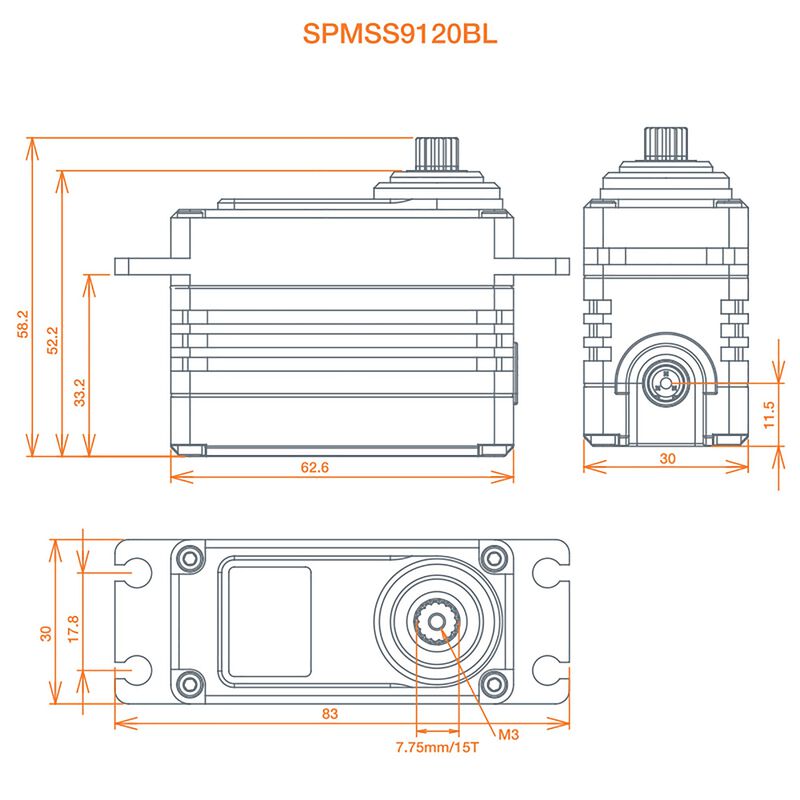

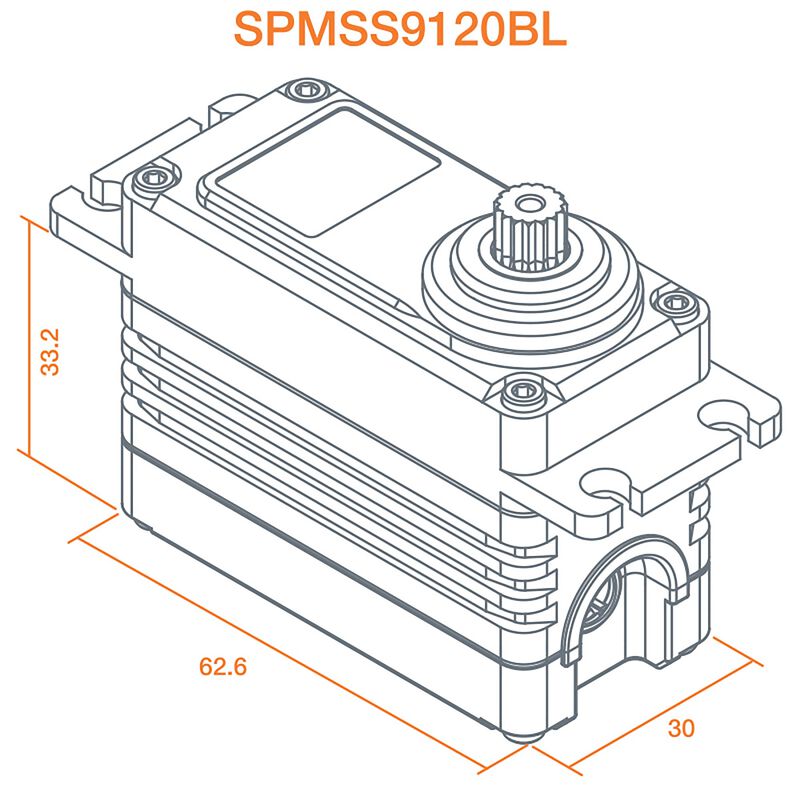

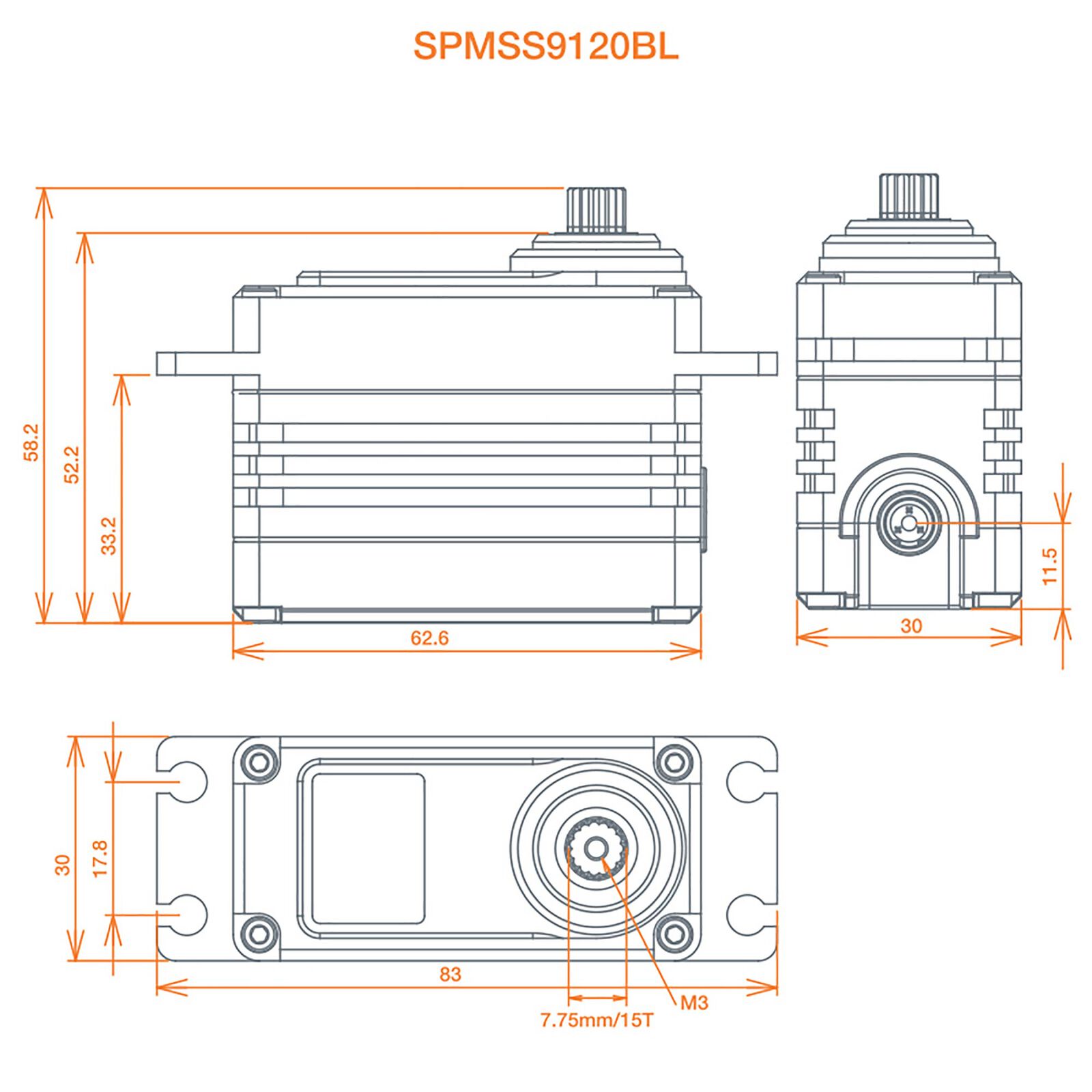

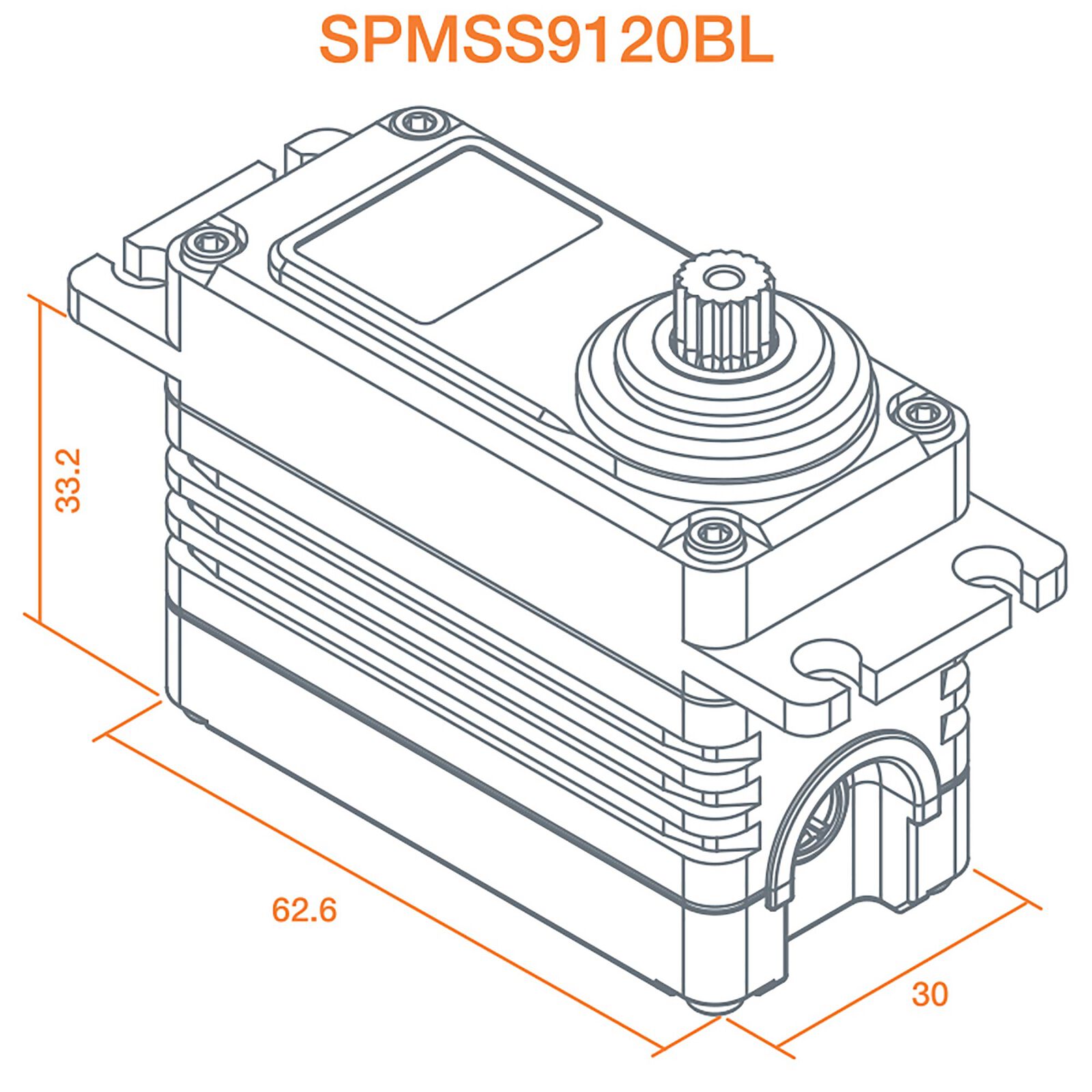

Starting with a new case design with improved support for pins holding the gears, and a new aluminum top plate with re-designed bearing house, the S9110 and S9120 have been design for improved durability. A new brushless motor design will give more power than any previous Spektrum servos – the high torque S9120 is rated at 1454 oz-in of torque at 8.4v, while the high speed S9110 is rated at 1224 oz-in of torque. The S9110 keeps a similar speed of 0.14 sec/60⁰ at 8.4, while having almost 60% more torque than the previous version! Additional improvements include a sleek new stealth black design and new thicker 18awg wire detachable connector. What’s more, both are already race proven, the S9110BL and S9120 having won the 2020 1/5 Worlds Buggy Class at So Cal Nitro.

No matter if you choose the higher speed S9110BL or the higher torque S9120BL, these servos will give higher performance and additional control whether racing your 1/5 vehicle on the track or bashing through dunes.