Discontinued

|

This Item is No Longer Available

S6280 Standard Digital HV Ultra Torque High Speed Waterproof Metal Gear Surface Servo

Item No.

Spektrum -

SPMSS6280

$144.99

Discontinued

|

This Item is No Longer Available

S6280 Standard Digital HV Ultra Torque High Speed Waterproof Metal Gear Surface Servo

Item No.

Spektrum -

SPMSS6280

Selected Store

S6285 1/8 High Voltage High Torque Metal Gear Race Servo

SPMSS6285

Product Details

Quick Links

Manuals & SupportKey Features

- Removable wire harness with different lengths available

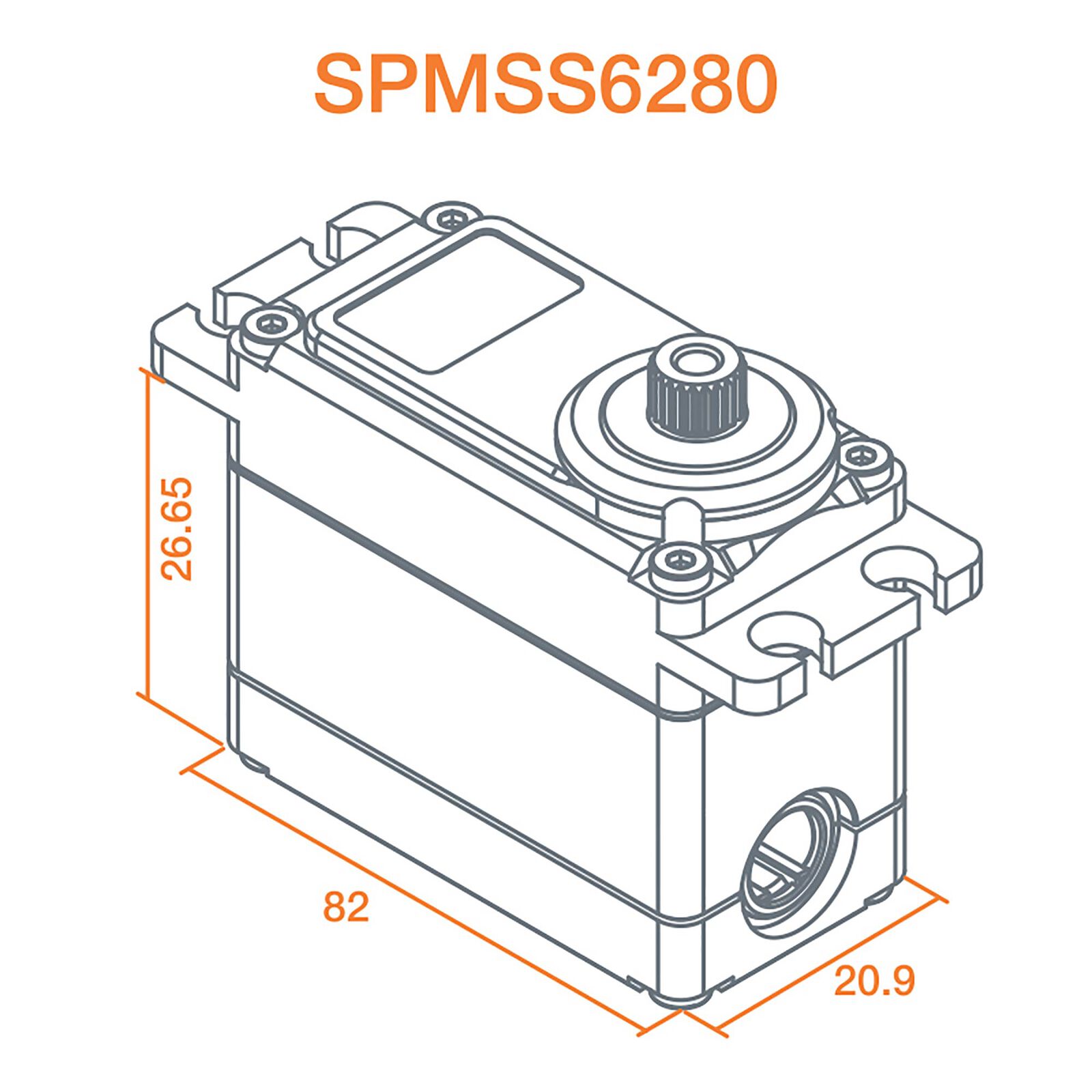

- 7075 Aluminum hard anodized output shaft/main gear with steel internal gears

- Aluminum case for good heat dissipation

- Aluminum mounting tabs

- NMB dual main bearings

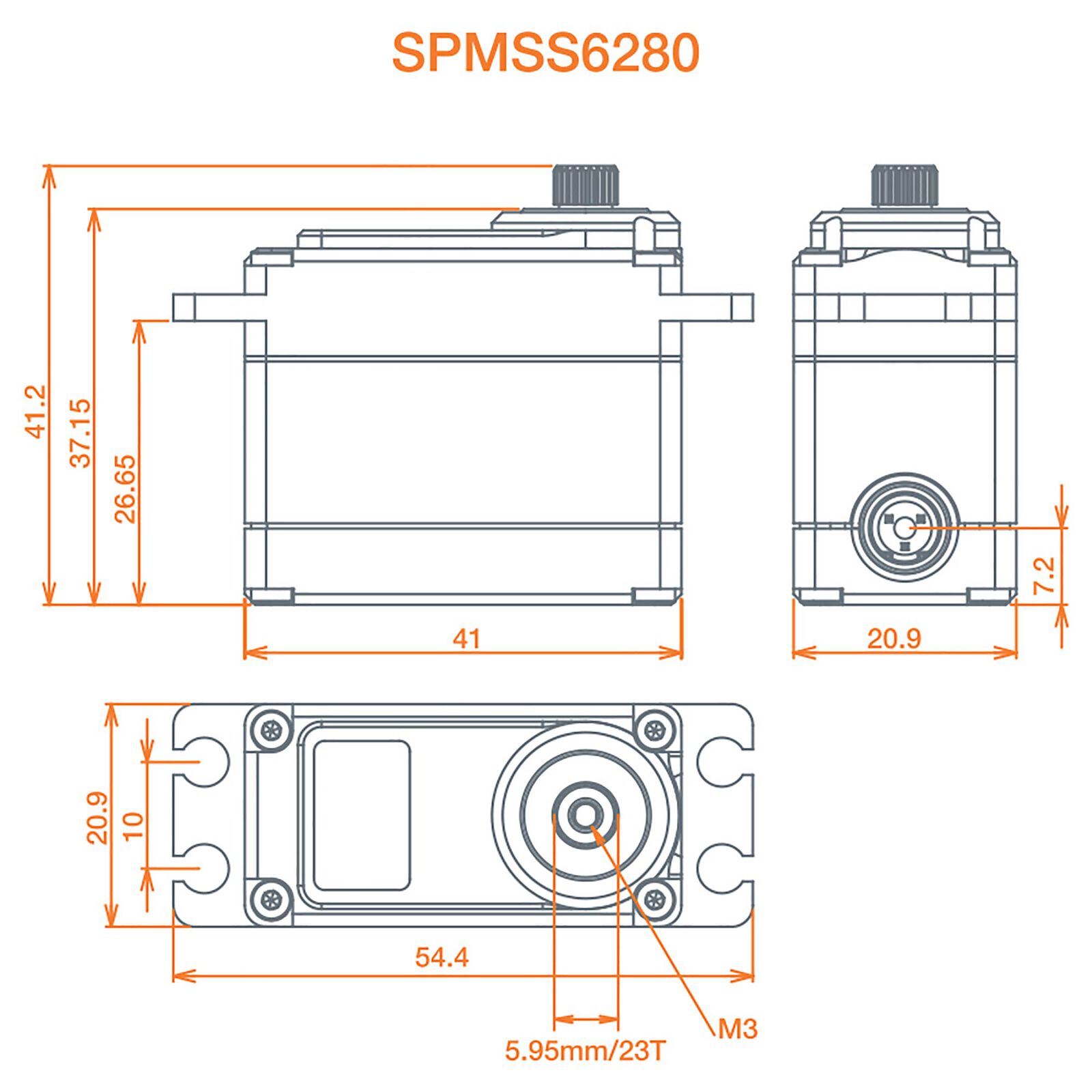

- 23T output shaft

- Waterproof

- 1-Year Limited Warranty

Overview

The latest generation of Spektrum surface servos provides you with the performance you need for any 1/10th to 1/8th scale vehicle application. The S6230 and S6240 offer high-torque or high-speed performance in a more compact size for 1/10th scale crawlers or monster trucks where space is limited. The S6250 HV and S6260 HV are standard size servos for High-Voltage applications up to 8.4V, And the S6280 HV and S6290 HV feature all metal case construction for the ultimate 1/8th scale performance. All these servos feature Spektrum innovations like the removable wire leads that allow for custom lead length and ease of maintenance and all metal servo mounting tabs to keep them in place through the most extreme conditions.

Product Specifications

| Bearing | Dual |

| Bushing Or Bearing | Bearing |

| Gear Type | Metal |

| Current Draw Stall | 4900mA @ 6.0V |

| Motor Type | Brushed |

| Servo Operating Voltage | 6.0 - 8.4V (HV) |

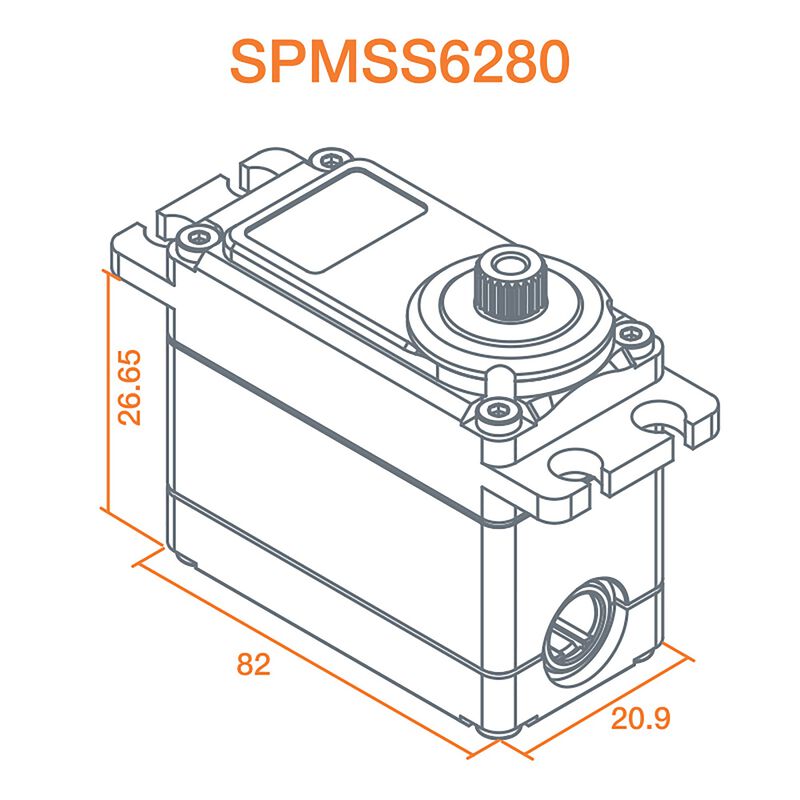

| Product Length | 1.61 in (41mm) |

| Maximum Servo Torque | 364 oz-in (26.2kg-cm) @ 6V; 440 oz-in (31.7kg-cm) @ 7.4V; 496 oz-in (35.7kg-cm) @ 8.4V |

| Application | Surface |

| Product Weight | 2.8 oz (79.4g) |

| Spline Count | 23 Teeth |

| Current Draw Idle | 10.2mA @ 6.0V |

| Product Width | 0.82 in (20.8mm) |

| Part Type | Electronics |

| Product Application | Surface |

| Product Height | 1.38 in (35.1mm) |

| Servo Type | Digital |

| Material | Metal |

| Programmable | No |

| Servo Size Category | Standard |